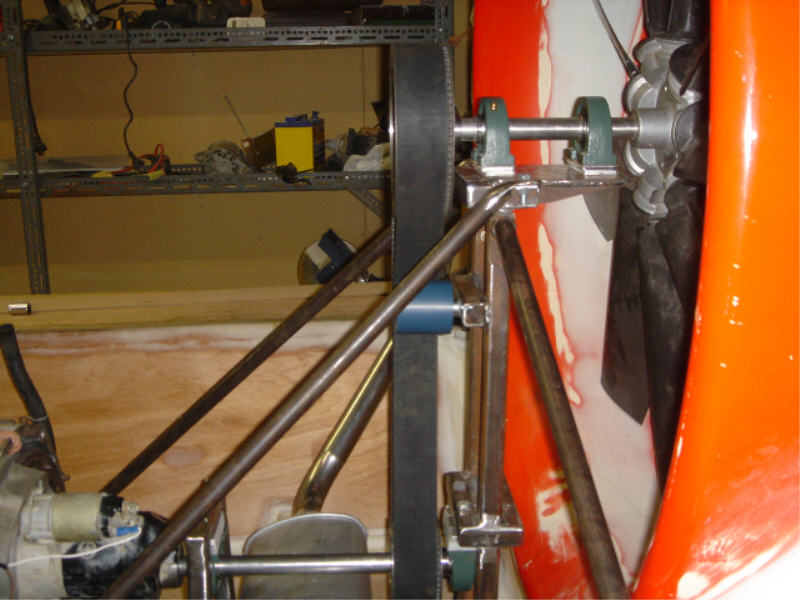

Today i welded and extra section of box tubing to my fan frame and drilled a slotted hole in one end so that i can mount a tensioner to adjust the excess slack i have in the belt i had to buy. At the moment, as it sits, the belt on the fan shaft try’s to walk towards the front of the craft when i turn the fan by hand so i still have a slight alignment issue to work out yet, but overall the pulley alignment doesn’t look to be that far out when using my “eye-ometer” 🙂

The belt i wanted to buy was a little smaller than the one i got but was not readily available in NZ, so i went with a slightly longer belt that’s more common here in NZ. Either way i’m sure i would of had to make a tensioner anyway. This picture is really just showing the belt fitted and tensioned. Pity the tensioner i bought only comes in blue, a black one would of been nicer 🙂

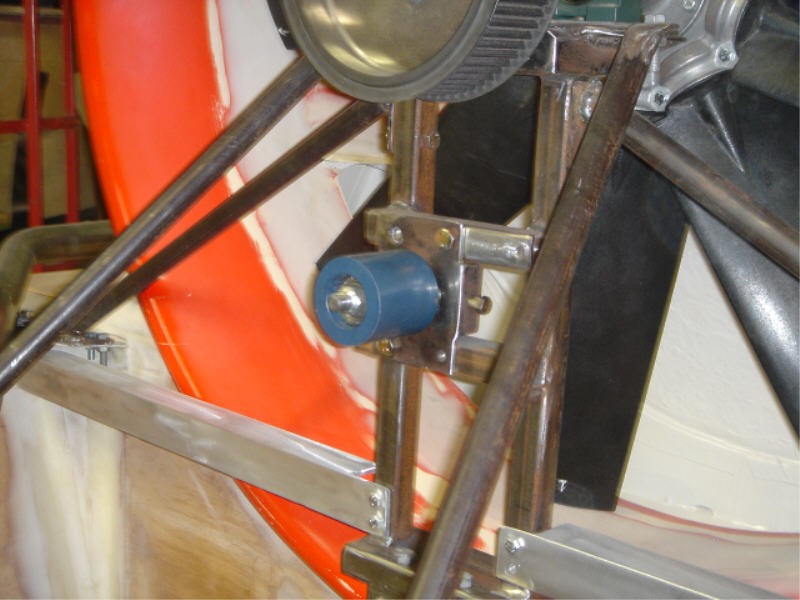

Belts back on again and now i still have a little bit of tweaking to do to get the belt running perfectly before i bite the bullet and start it up all connected. I mounted the tensioner to a square plate that is attached to the frame by four bolts. The reason for that was so that i can put spacers behind either of the 4 bolts to align the tensioner with the belt.

Since the previous pictures i have now come back to earth and mounted the tensioner on the correct side of the belt. I have no idea why i started to mount it on the drive side of the belt when i knew that it should be on the slack side of the belt , i guess it was late when i done it. Anyway its all fixed now and i even mounted a adjuster to the back of the tensioner so that i can now adjust the belt tension by winding in on the adjuster bolt.