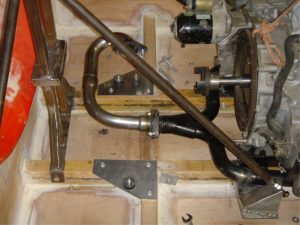

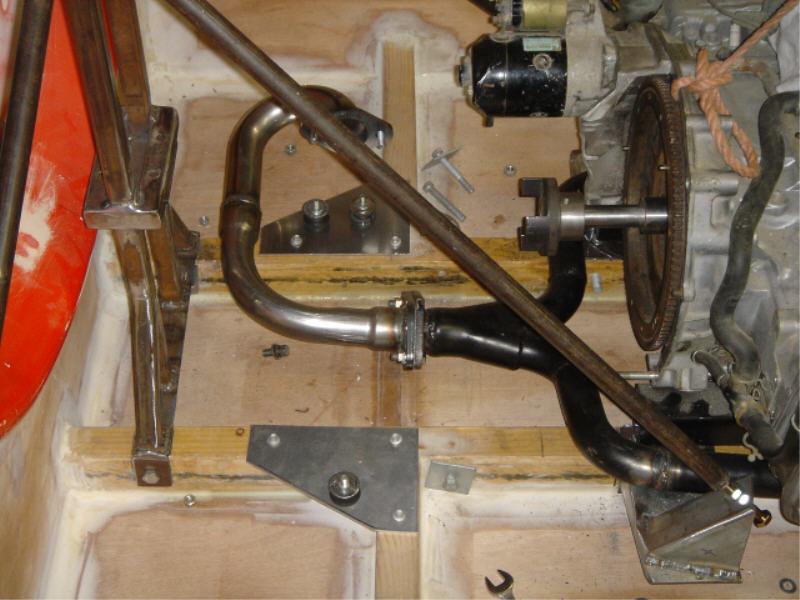

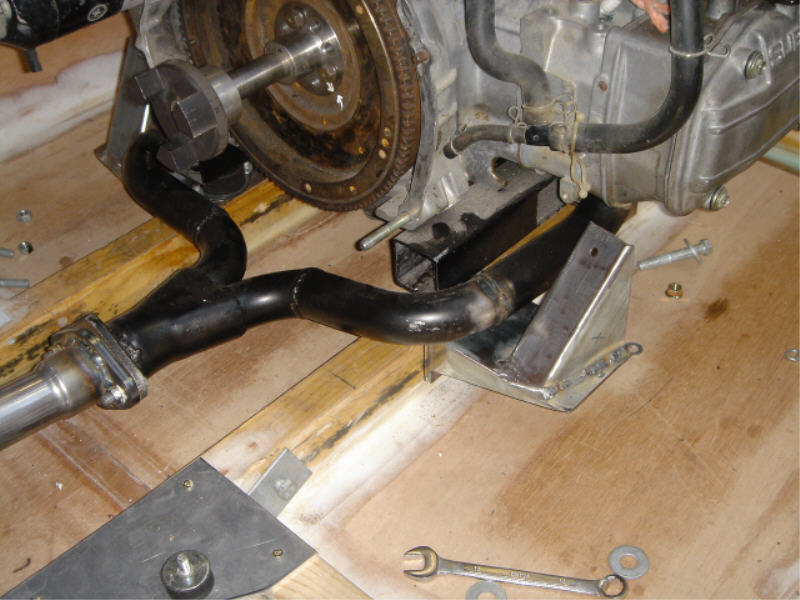

Apart from painting it and a little tidying up, the exhaust is now finished. The pipes were bent up by Magoo Mufflers on their pipe bender and the front pipes from the manifold were also created by them. I screwed some aluminium plates to the beams on the floor and then mounted rubber exhaust mounts to absorb vibrations from the exhaust.

Here’s another shot with the muffler and tailpipe fitted. i was going to get the exhaust done in stainless steel, but the engineer’s bill will arrive this month as well as many others so i thought i better save some money somewhere along the line to pay for it all 🙂

After considerable time thinking of ways to mount the front support bars from my fan frame i came up with this idea. What i’ve done is took my original L shaped brackets that mount the rear engine mounts to the floor and cut up a length of box tubing welded them both together and ‘wa la’ this is a what i ended up with. The next couple of pictures will show what it does 🙂

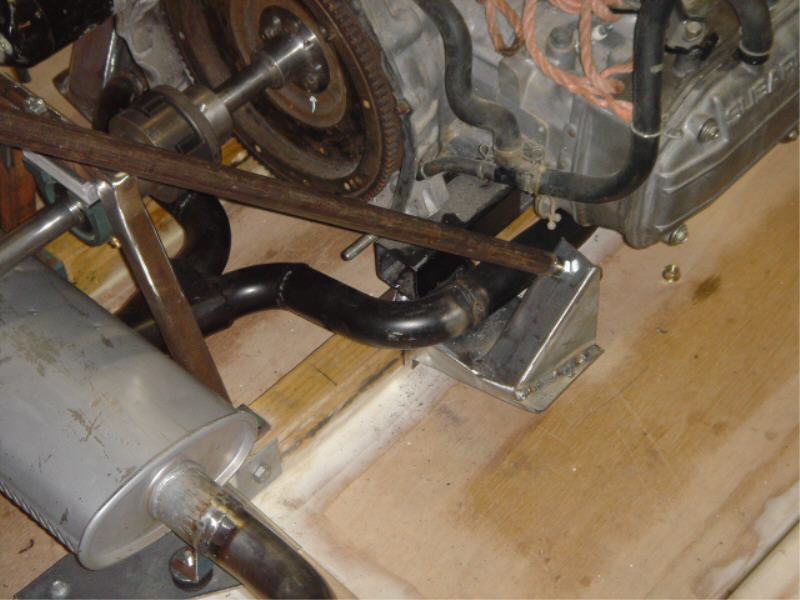

The front engine mounts have 1 * 12 mm galvanized bolt per side that attach’s the mount to the floor, the rear mounts have these two holes per side to try and spread the load that the fan support bars will have on it.

Here the brackets are fitted in place and by having the brackets up higher like this rather than to a different bracket on the floor means that the support bars are closer to a 45 degree angle which should in theory make them carry the load alot better

The front fan frame support bar is now fitted. Down near the bracket end i cut the support bars short of the bracket and welded a nut to the end of them, i don’t know if it’s a positive move or a negative move but i done that so that i can screw a bolt through the bracket’s i just made and into the support bars so that they are adjustable. That way if there is ever a need to adjust the angle of the fan frame i can do so by tweaking the bolts at the end of the support bars.